Real-Time

Robotic Motion Library

Using industrial robots for communication purposes creates some very interesting practical problems. Industrial robots have traditionally been controlled by fixed programs and typically work self-sufficiently. They are linked to surrounding machinery only by very simple commands, which make production processes as simple and efficient as possible.

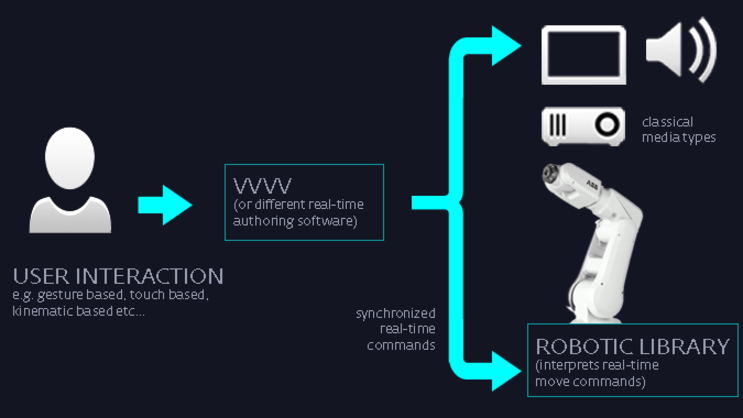

The use of industrial robots in creative applications, however, brings other important requirements like tight integration with the users’ actions or synchronization with media.

The fact that a robot reacts directly to an external inputs is not only required for interactive exhibits, but also simplifies the design process. To allow this, RT/RML was developed, which runs on the ABB robot controller and reacts to commands “on the fly” without needing to reprogram the robot controller.

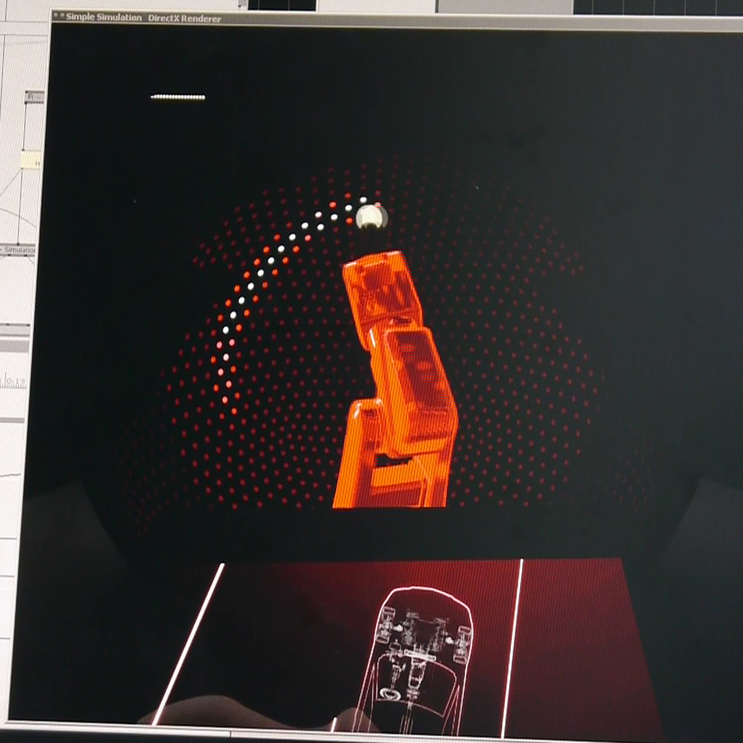

RT/RML regards the robot as a stateless machine which is slaved to an external authoring system such as vvvv. The advantage of this approach is that the robot’s movements can be very easily synchronized with content generated for other media, such as displays, projectors, audio, and other kinetic elements. All commands are sent via TCP/IP, so that the robot can be actuated from any external system without problem.

Principle of MESO Robotics

© MESO Digital InteriorsPhysical Pseudo-Physics

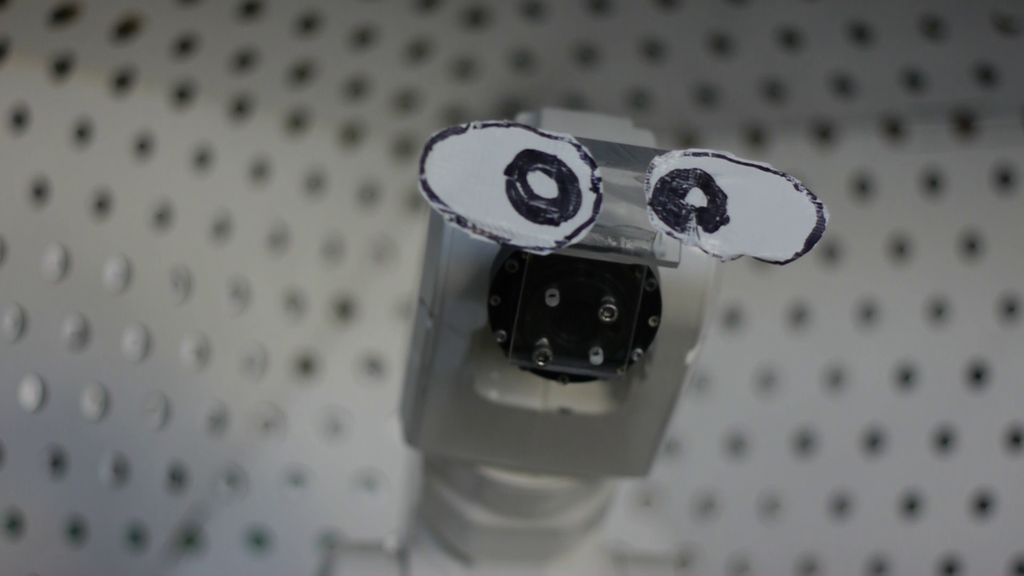

In contrast to the use of robots in production processes, applications in communication design place high emphasis on the exact characteristics with which a robot moves. The robot’s movement should satisfy aesthetic and choreographic criteria to give the impression of an individual personality with specific behavior. This requires precise control of the robot’s movements.

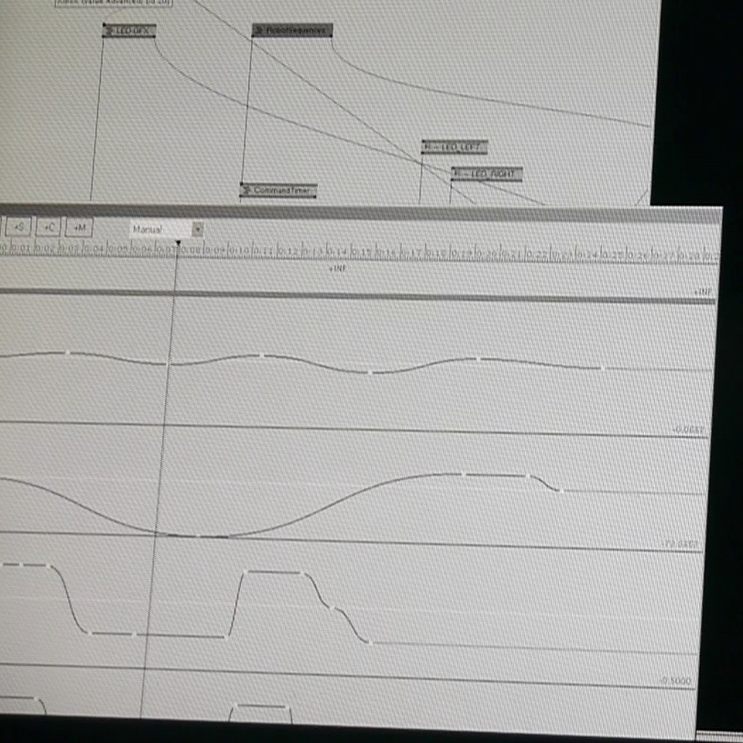

The RT/RML implements various algorithms in order to control the aesthetics of the movements: for example, the robot may execute a journey between two points in a “slow and subdued” or a “wildly reckless” fashion, without any great programming effort. The RT/RML simulates a virtual physics with a given mass or agility over the real physics of the robot. This allows very elegant, plausible movements, while leveraging the robot’s highly developed dynamics.

Additional algorithms include:

- Suspension – physical spring suspension model separately adjustable for rotations and translations. Rotations around any points.

- Bézier curves – movement along a curve defined by two handles.

- Tweens – different modes to modulate the speed during a movement.

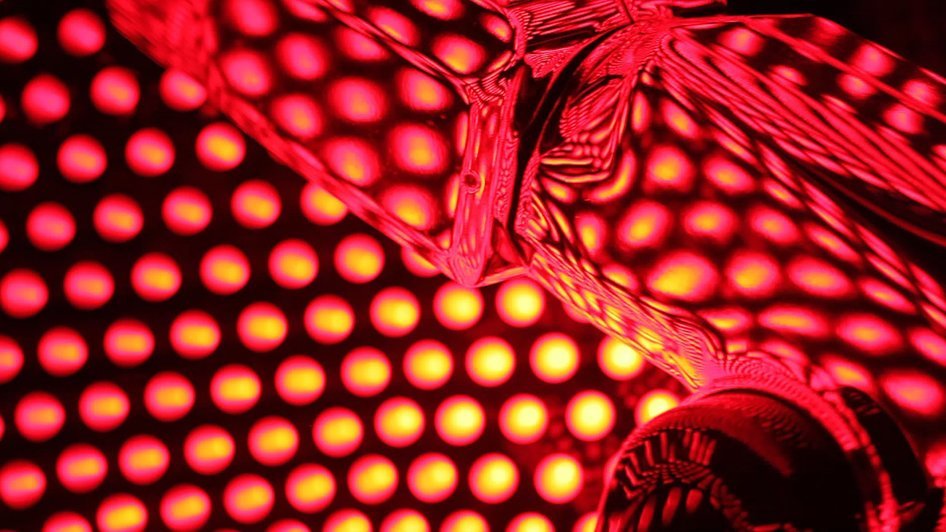

Paradigmatic examples of RT/RML applications from the MESO laboratory are shown in the following:

Curious about our approach? Feel free to get in touch!

Sebastian Oschatz Partner +49 69 24 000 321 sebastian.oschatz@meso.design sebastian.oschatz@meso.design +49 69 24 000 321

MESO Digital Interiors GmbH

Gutleutstr. 96 . 60329 Frankfurt . Germany

Team

David Brüll, Jochen Leinberger, Nikos Mechanezidis, Tebjan Halm, Elias Holzer, Friedrich Söllner, Martin Wagner