Cross-Medial Scenography

Exhibits, Samples, And the Digital Age

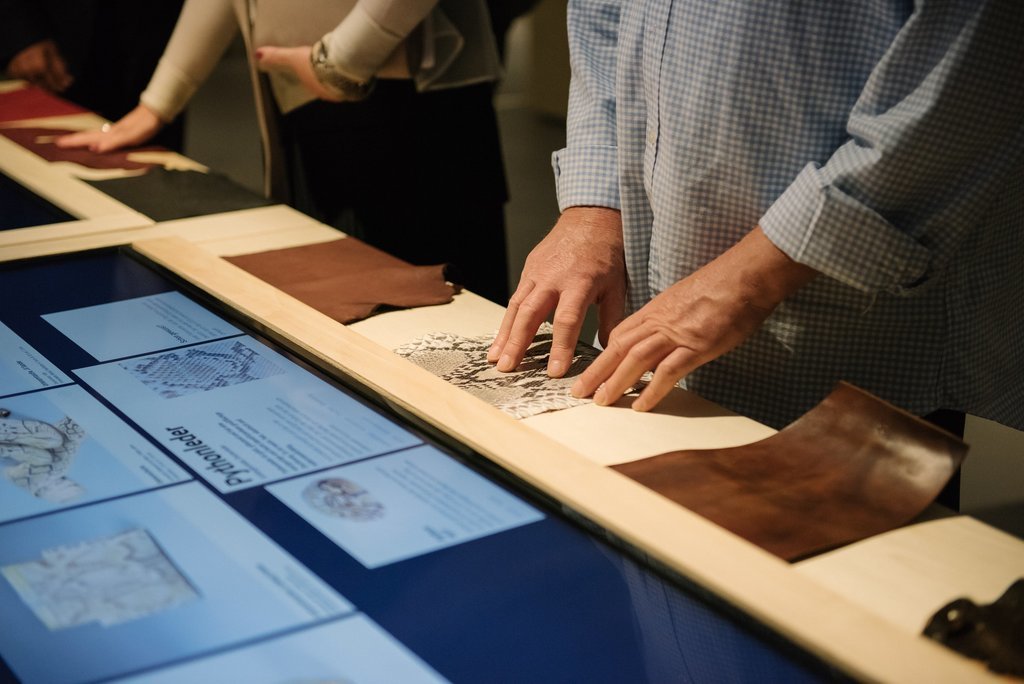

Museums tend to secure their exhibits behind glass or barriers. Especially when it comes to pieces of extraordinary surface qualities, though, visitors feel the natural urge to explore them not only with their eyes but also with their hands. The same is true for Deutsches Ledermuseum, a museum based in Offenbach housing over 30,000 leather objects from all over the world, some of them dating as far back as 4,000 A.D.

In a refurbished space on the museums’s ground floor, the exhibition “Das ist Leder! Von A bis Z” (This Is Leather! From A to Z) gives an overview of the versatility of leather and its different uses over the centuries. As part of this new approach, all historical objects displayed in glass cabinets are complemented by the corresponding material samples.

Also, the museum draws on digital media for the first time ever, taking a step towards a modernized overall concept. The wide range of leather types – from thick cowhide to brittle python skin – is highlighted by eight media tables.

The new media exhibition contributes an essential part to the repositioning of the museum within the cultural landscape.

Visitors can not only experience these samples with all senses, their touch also activates the display of detailed information on special features, application examples from the museum’s collection, workmanship, and finishings on the screens.

Agile Data Management

Digitalizing The World of Leather

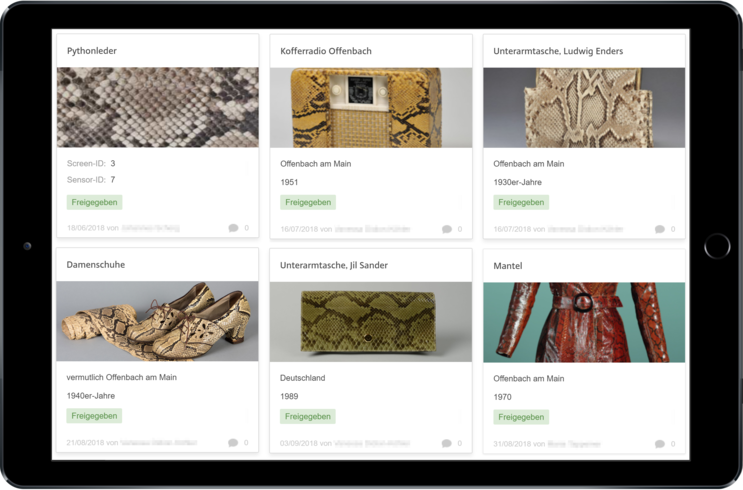

Even though MESO remains the museum’s partner in maintaining the exhibition, it was important to give the curators the possibility to independently edit the content presented on the media tables. Therefore, the intuitive user interface draws on a low-barrier CMS. The challenge of narrowing down an extensive database to the key facts important for the general public is supported by an agile structure allowing for constant update while the collection is in the process of digitization.

To create an extensive digital archive as content for the media tables, images of the original exhibits, descriptive information as well as meta data associating every object with the corresponding physical hardware sensor had to be merged in one database. Today, a total of 180 historical pieces is presented in the exhibition. The museum staff can access and update this data independently online as well as integrating alternative or additional samples any time.

Also, the database now set up could serve as a valuable starting point for future projects.

Custom Interaction Concept

An Exhibition Accessible To Everyone

Visitors at the museum include all age groups, from young children to elderly people, some of them deeply rooted in the tradition of Offenbach’s former leather industries. In order to meet these diverse demands, the task was to eliminate barriers and present all information as easily accessible and self-explanatory as possible.

The integration of the leather samples proved to be the perfect way to stimulate an intuitive and sensual handling of the digital content.

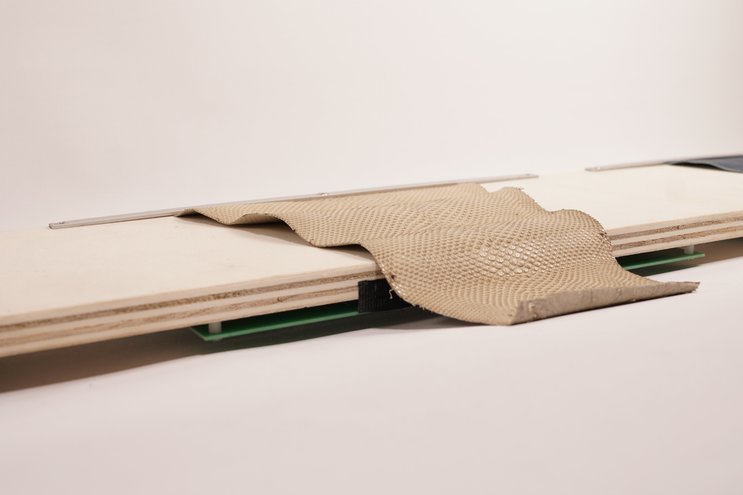

As the technological framework remains hidden within the tables, the scenography is kept simple and all attention lies on the exhibits.

Making-of

Low-Budget Meets High-Tech

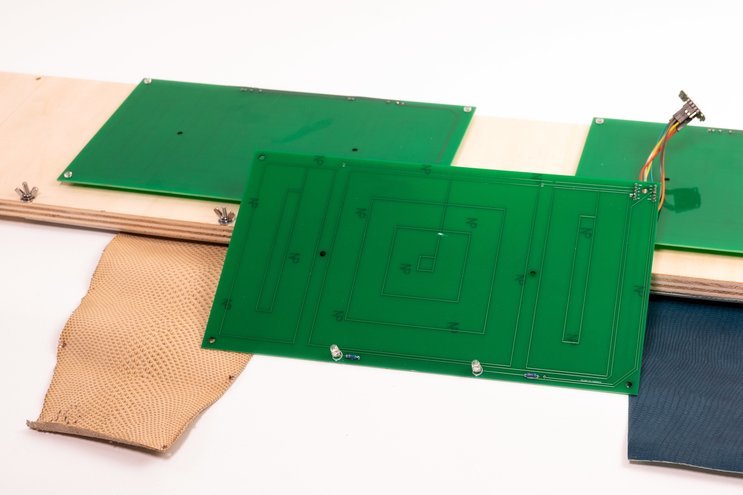

In contrast to a temporary installation, the media tables are there to stay – meaning they need to be robust and easy to maintain. Therefore, we opted for effective low-lech hardware.

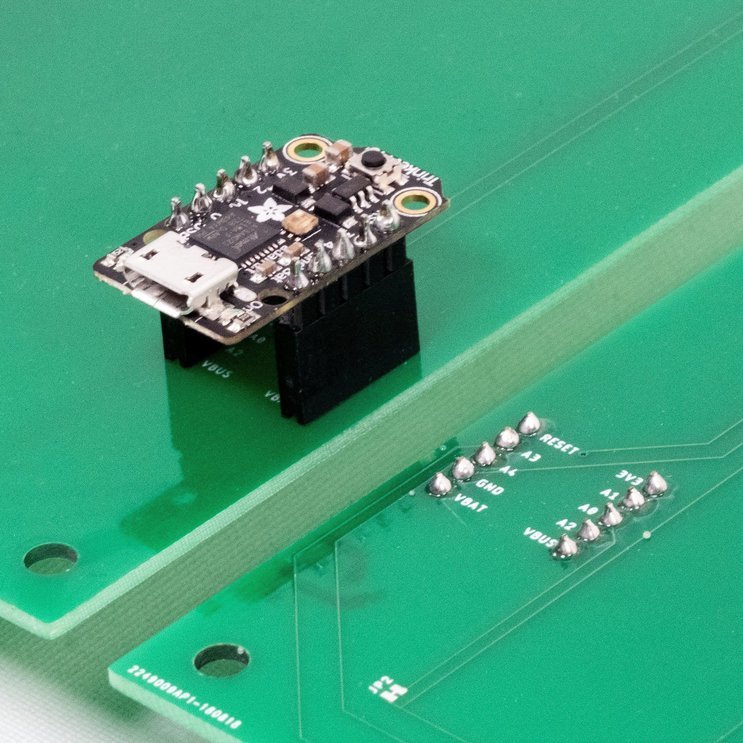

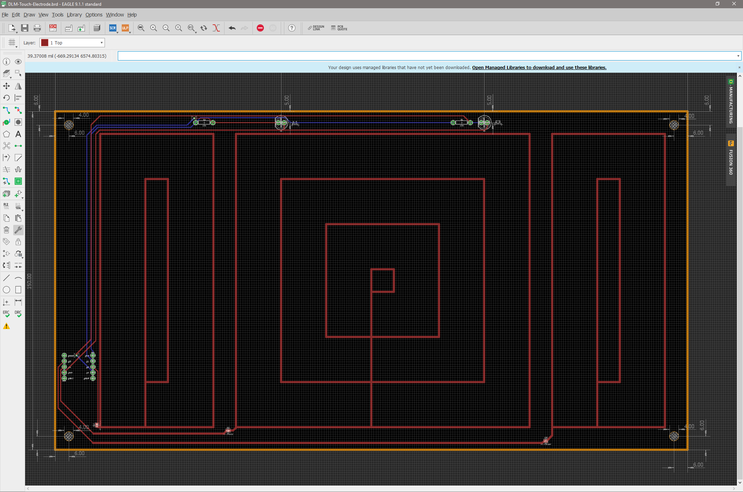

The heart of the interactive experience are 64 capacitive/optical sensors that were produced in a professional large-scale PCB factory in China – an approach made possible by our specialist knowledge on embedded systems.

Tailored for this application in their sensitivity, the sensors react precisely to the visitors touch and allow a fine-tuned connection of physical and digital experience.

From mass item to bespoke technology: in combination with the custom manufactured circuit boards, low-budget microcontrollers turn into advanced touch sensors.

All sensor boards were tested individually in our own electronics workshop, fitting them with microcontrollers and individual components.

Curious about our approach? Feel free to get in touch!

Sebastian Oschatz Partner +49 69 24 000 321 sebastian.oschatz@meso.design sebastian.oschatz@meso.design +49 69 24 000 321

MESO Digital Interiors GmbH

Gutleutstr. 96 . 60329 Frankfurt . Germany

Team

Johannes Scherg, Jonas Häutle, Timon Skerutsch, Anton Viehl