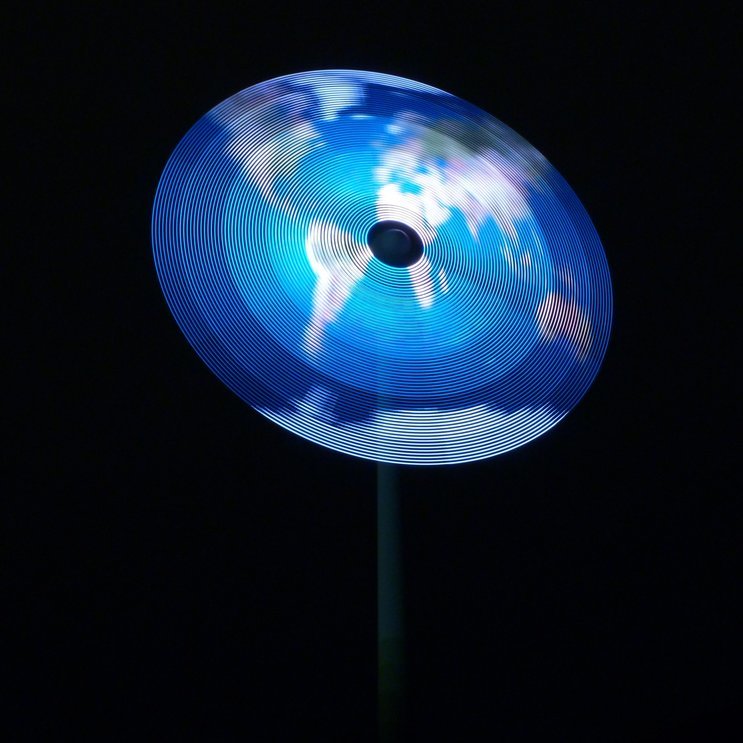

On the occasion of the 2009 Copenhagen Climate Summit, media artist Michael Pendry cooperated with Siemens to create a unique light installation for a wind turbine located on a hill next to the Allianz Arena in Munich. Within a tight time-frame, we implemented a system to display motion graphics on the rotors of the wind turbine. Our real-time programming transformed the 9,000 LEDs of our partner Traxon Technologies into a beaming symbol for climate protection and made sustainable energy production visible to the public.

“Der Stern des Südens”

Probably the biggest rotating light installation

The “Stern des Südens” is a beacon of innovation and green energy. Pendry’s concept was to disassociate the subject of “art” from the closed spaces of museums and galleries and make it publicly accessible.

Early on, we took on the role of technical adviser to the project. After evaluating various technologies, we chose LED experts Traxon Technologies as our project partners. With the help of the latest light technology and our smart data-feed, we created a unique play of light that could be discerned from more than 30 km away.

The “Stern des Südens” is not only an innovative piece of media art but also an example of our use of sustainable use of energy in our project repertoire. All LEDs receive their electricity directly from the wind turbine.

The Siemens Southern Star is a technological pioneering achievement and an important symbol for the upcoming world climate conference in Copenhagen.

A special “Easter egg” was shown to journalists and photographers:

Our media system projected the lights on the spinning rotor blades in such a way that a long photographic exposure reveals images.

Smart media integration

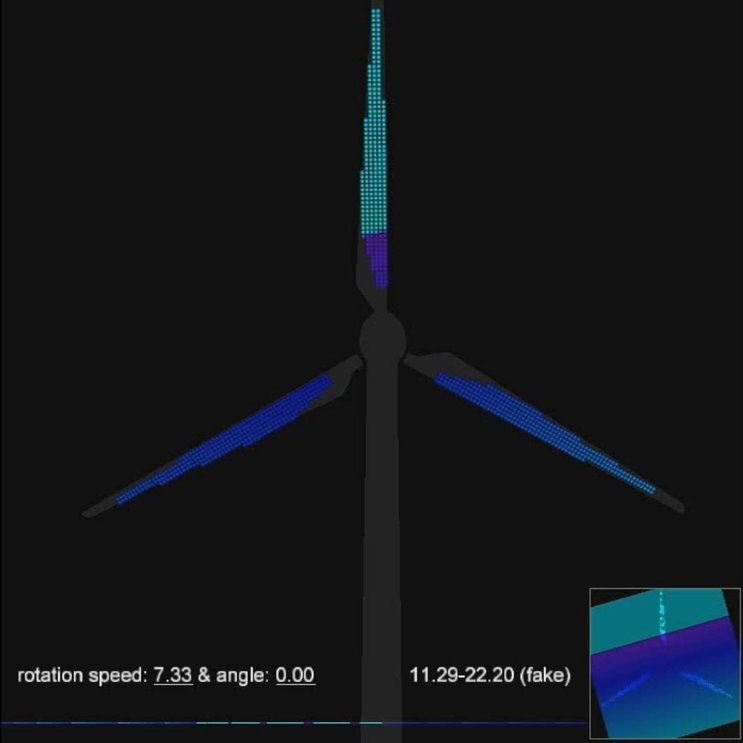

Realistic simulation enables for rapid setup on-site

The 9,000 LEDs were programmed by us to be controlled in real time. During the prototyping process we developed a 3D simulation of a wind turbine and were thus already able to develop various display scenarios during the concept phase.

The roll-out of the project was characterized by a very tight schedule of only two nights. In order to be able to test all functions on-site for operational safety, the main task was the technical planning and the preparation of the project.

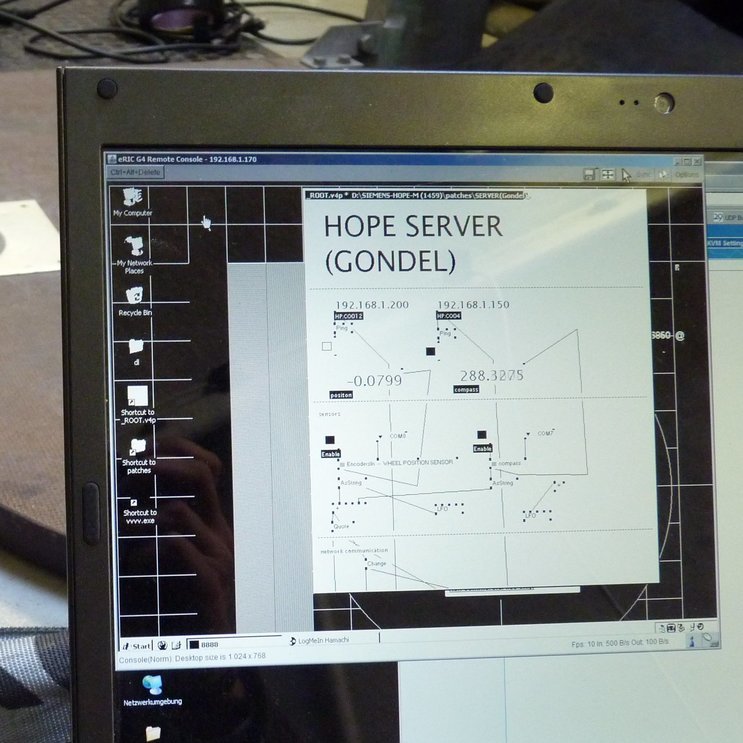

We were not allowed to make any changes to the turbine itself. Therefore we skillfully integrated our entire sensor system without any electronic or mechanical connection to the electricity generator or the control electronics.

The computer source for the signals was placed in the rotating hub of the turbine, hooked up to an already present electronic plug (usually used for maintenance purposes), and connected to the outside work space via Wi-Fi. Siemens technicians mounted the computer.

In order to capture the precise position of the rotor blades, we developed an optical sensor system that scanned the movement of the generator coils.

The orientation of the turbine towards the wind was measured by a magnetic sensor.

The visual quality of the light show only became visible after dark.

We established a mobile office, in order to have a continuous view of the light display on the front of the rotors despite changing wind directions.

A Wi-Fi-based VNC connection allowed for calibration of the software and the optimization of the motion graphics from the comfort of a camper positioned by the side of the wind turbine.

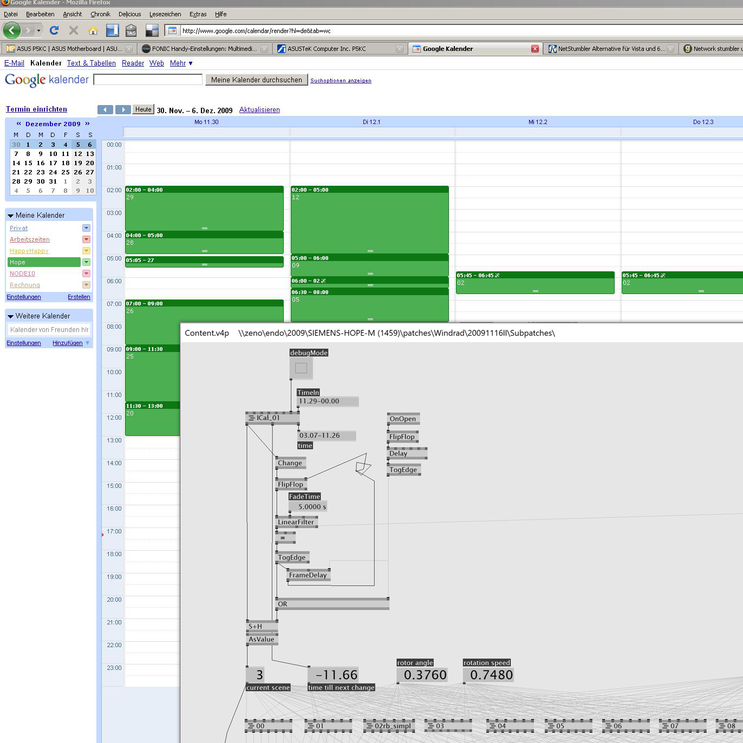

A playlist and planning functionality for the content ensured all media content on the roster could be displayed at the time of the opening without disturbance.

This function was generated spontaneously on site. This demonstrates our vast experience in agile prototyping and our technical diversity in ideas.

Making-Of

Behind the scenes

Working at high altitude: Siemens technicians fit each of the three rotor blades of the turbine with nearly 100 feet of over 9,000 Traxon Technologies DotXL RGB LEDs.

Curious about our approach? Feel free to get in touch!

Sebastian Oschatz Partner +49 69 24 000 321 sebastian.oschatz@meso.design sebastian.oschatz@meso.design +49 69 24 000 321

MESO Digital Interiors GmbH

Gutleutstr. 96 . 60329 Frankfurt . Germany

Team

Max Wolf, Ingolf Heinsch, Alexander Graf, Andreas Brendle